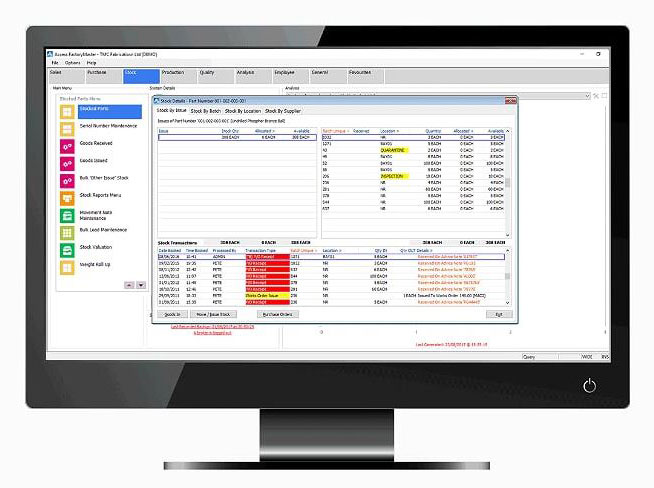

At Helix Precision we understand the importance of traceability it is undoubtedly a major issue across the manufacturing sector. The only way to deliver consistent, accurate performance in response to traceability challenges is to have instant access to all the right information. Due to the investment in Factory Master MRP system we have full traceability at every individual element in the production cycle back to source and show an audit trail at every stage from goods in to delivery. Should a customer have any problems with parts in the field they need answers and fast, we could answer the below 5 questions for every component with an issue we have manufactured in our factory right now!

Traceability

Which Batch did it come from?

Which batch is affected?

Which processes have been used to make the part?

Where are all affected parts now?

Who signed it off?

Key Advantages of Working with Helix

We Can Trace every individual element in the production cycle back to source and show an audit trail at every stage from goods in to delivery.

We Can Identify every batch, component or raw material movement, including when it was produced or arrived on site, who accepted it, and final point of delivery.

We Can See who inspected an item prior to use within the production environment, and who gave approval at each stage of production.

We Can Follow a complete audit trail from start to finish and instantly source evidence, including POs, delivery notes and inspection reports.

We Can easily identify a non-conforming part, which batch it came from, when it was produced, which products has it been used in and where are these now.

We keep all your certificates of conformity and associated quality documents in one place, against the finished batch.

We can accommodate multilevel assemblies and multiple components.